CX-0041 Acpect Model: Manufactured Parts Quality Information v1.0.2

1. Introduction

This document describes the semantic model "Manufactured Parts Quality Information " used in the Catena-X network.

1.1 Audience & Scope

This section is non-normative

The described semantic model is relevant for:

- Data Provider / Consumer

- Business Application Provider

1.2 Context

This section is non-normative

The Catena-X use case Live Quality Loops (QAX) uses multiple data models to exchange data between automotive manufacturer (OEM) and component supplier (TIER1). Each of these data models can be supplied independently.

The data model ManufacturedPartsQualityInformation is a set of manufacturing-related properties of a produced part/component that could be relevant to solve a quality task.

1.3 Conformance

As well as sections marked as non-normative, all authoring guidelines, diagrams, examples, and notes in this specification are non-normative. Everything else in this specification is normative.

The key words MAY, MUST, MUST NOT, OPTIONAL, RECOMMENDED, REQUIRED, SHOULD and SHOULD NOT in this document are to be interpreted as described in BCP 14 [RFC2119] [RFC8174] when, and only when, they appear in all capitals, as shown here.

1.4 Proof of conformity

This section is non-normative

All participants and their solutions will need to prove they conform with the Catena-X standards. To validate that the standards are applied correctly, Catena-X employs Conformity Assessment Bodies (CABs).

For Data Provider: To prove conformity you have to fulfill all MUST criteria mentioned in chapter Normative criteria for Data Provider.

There is no proof of conformity necessary for Data Consumer.

For Business Application Provider: To prove conformity you have to fulfill all MUST criteria mentioned in chapter Normative criteria for Business Application Provider.

A model validator must be created, to prove the correctness of the data model. A generic test set created for the model must prove the expected results.

1.5 Examples

Example payload in JSON format:

{

"listOfManufacturedParts":[

{

"manufacturerId":"123-0.740-3434-A",

"manufacturingInformation":{

"date":"2022-02-04T14:48:54",

"hasBeenReworked":false,

"country":"DEU",

"productionLine":"Line_1",

"plantDescription":"Feuerbach Plant",

"plantId":"00001",

"batchId":"20220204_466",

"addtionalInformation":[

{

"value":"Stainless steel",

"key":"Steel quality"

}

],

"numberOfConductedEOLTests":1

},

"catenaXId":"urn:uuid:580d3adf-1981-44a0-a214-13d6ceed9001",

"qualityTaskId":"BPN-811_2022_000001",

"nameAtManufacturer":"Steering assembly",

"manufacturerSerialPartNumber":"436347347.4343884384.FTG.538348"

}

]

}

1.6 Terminology

This section is non-normative

Business Partner Number (BPN)

A BPN is the unique identifier of a partner within Catena-x.

2. Aspect Model Manufactured Parts Quality Information

2.1 Introduction

Catena-X use case "Live Quality Loops"(QAX) uses several Catena-X standardized data models to exchange data:

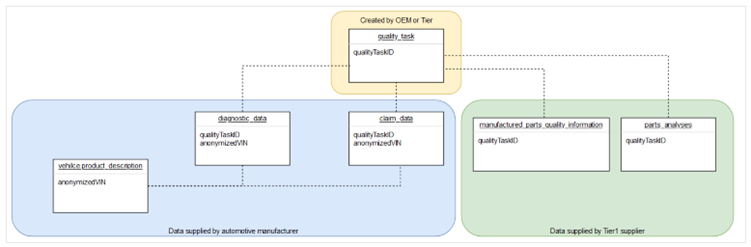

Figure 1: Hierarchy of Catena-X data models used in QAX

Data models in QAX and their content:

-

QualityTask is the root element and describes why companies are working together on a quality topic and what they want to do. All involved companies and their contact people are named. In addition, a flag tells what should be done with exchanged data after a QualityTask is closed.

-

Vehicle.ProductDescription: This data model is a representation of one vehicle affected by this QualityTask. The model represents the vehicle when it was sold to the end-customers from an end-customers point of view: Which standard equipment was installed in the vehicle and which extra equipment was installed in the vehicle.

-

Fleet.DiagnosticData: Diagnostic data coming from multiple vehicles that are affected by this QualityTask + Diagnostic data from similar vehicles that are not affected by this QualityTask.

-

Fleet.ClaimData: Customer complaints that are linked to this QualityTask + Data about the exchange of potentially faulty parts

-

ManufacturedPartsQualityInformation: A selection of manufacturing-related parameters that help to solve the QualtiyTask

-

PartsAnalyses: Analyses results of replaced and potentially faulty parts that are linked to this QualityTask

2.2 Normative Criteria

The usage of the described semantic model "Manufactured Parts Quality Information" is a MUST for Data Provider and Data Consumer that want to work together on a quality topic over Catena-X automotive network.

2.2.1 Normative criteria for Data Provider

Every data provider of "Manufactured Parts Quality Information" MUST provide the data conformant to the semantic model specified in CX-0041.

If available a data provider of "Manufactured Parts Quality Information" MUST provide manufacturerSerialPartNumber for serial parts.

It is a MUST for data providers of "Manufactured Parts Quality Information " to provide the property qualityTaskId. qualityTaskId MUST match with qualityTaskId property of "Quality Task" data as defined in CX -- 0036.

If available batchId of the produced parts SHOULD be provided by the data provider.

If available catenaXId of the produced parts SHOULD be provided by the data provider.

In the Catena-X data space "Manufactured Parts Quality Information" MUST be exchanged via Eclipse Dataspace Connector (EDC) conformant to CX-0018.

It is RECOMMEND to use Apache parquet1 file format together with EDC S3 data plane for file data exchange for "Manufactured Parts Quality Information".

2.2.2 Normative criteria for Business Application Provider

It is a MUST for Business Application Provider to support at least 2 standardized Catena-X QAX aspect models from Catena-X release 3.0 to get the label "Catena-X Certified Solution" for their quality application.

It is RECOMMEND for Business Application Provider to be able to read the semantic model "Manufactured Parts Quality Information ".

2.3 License

This Catena-X data model is an outcome of Catena-X use case group Live Quality Loops (QAX). This Catena-X data model is made available under the terms of the Creative Commons Attribution 4.0 International (CC-BY-4.0) license, which is available at Creative Commons2.

The license information is available in github.

In case of doubt the license, copyright and authors information in github overwrites the information in this specification document.

2.4 Identifer of Semantic Model

This semantic model has the unique identifier

urn:bamm:io.catenax.manufactured_parts_quality_information:1.0.0

2.5 Formats of Semantic Model

2.5.1 RDF Turtle

The rdf turtle file, adhering to the Semantic Aspect Meta Model, is the master for generating additional file formats and serializations. It is provided here:

The open source command line tool of the Eclipse Semantic Modeling Framework3 is used for generation of other file formats like for example a JSON Schema, aasx for Asset Administration Shell Submodel Template or a HTML documentation.

2.5.2 JSON Schema

A JSON Schema can be generated from the RDF Turtle file using the Eclipse ESMF tooling. The JSON Schema defines the Value-Only payload of the Asset Administration Shell for the API operation "GetSubmodel".

If present, example JSON-payloads MUST validate against the generated JSON schema.

3. References

3.1 Normative References

- CX-0003 SEMANTIC ASPECT META MODEL

- CX-0004 GOVERNANCE PROCESS FOR SEMANTIC MODELS

- CX-0018 ECLPISE DATA SPACE CONNECTOR (EDC)

3.2 Non-Normative References

This section is non-normative

Legal

Copyright © 2024 Catena-X Automotive Network e.V. All rights reserved. For more information, please visit here.